Want better print results—are your blanks up to standard?

When print quality doesn’t look the way you expect, the first reaction is often to blame the printer or the ink. But in reality, the blank substrate itself plays a much bigger role than most people realize.

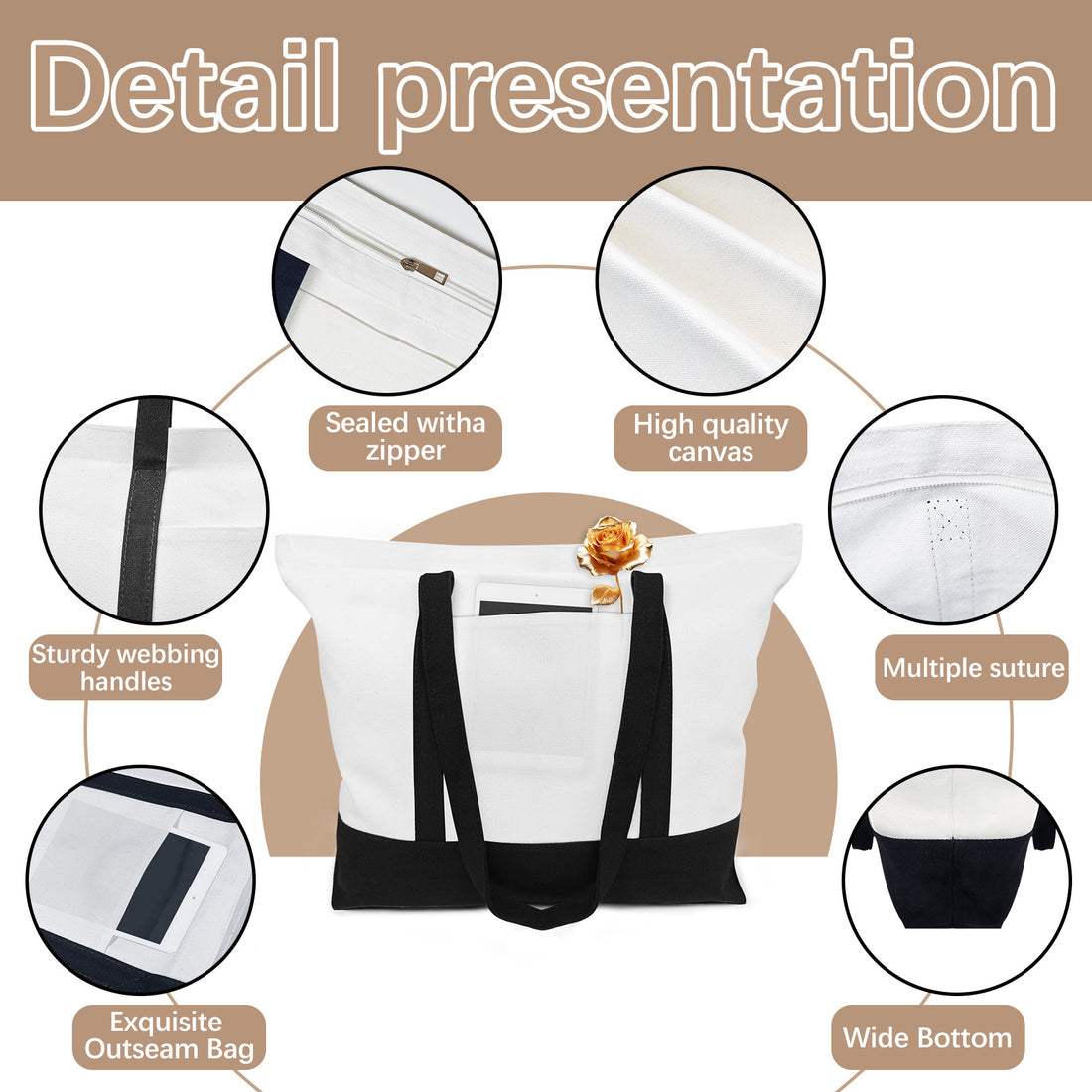

Think of your blanks as the “canvas” for your design. No matter how advanced your printer or vibrant your ink is, if the surface isn’t consistent, smooth, or properly treated, you’ll see issues like:

Colors looking dull or uneven

Ink bleeding or spreading outside the design

Poor adhesion, leading to fading after a wash or wear

Unexpected color shifts

What makes a blank “up to standard”?

Material quality – Fabrics or substrates should have even texture, no hidden coatings, and be sourced from reliable suppliers.

Surface treatment – Some blanks need pre-treatment for inks to bond well. Without it, results will vary.

Color base – Printing on a pure white or neutral blank gives more accurate color reproduction. Off-white or mixed shades can distort the final print.

Durability testing – Good blanks can withstand heat pressing, washing, and everyday wear without the print cracking or peeling.

Why it matters for your business

Using lower-grade blanks might save cost upfront, but the long-term effect is dissatisfied customers, higher return rates, and wasted ink. On the other hand, investing in high-standard blanks means:

Brighter, sharper prints

Consistent results across batches

Better customer reviews and repeat orders

Comments

Post a Comment